Selected references

| Client | Equipment | Goal | Content of harmful substances | Abatement efficiency, % |

HaloPolyme HaloPolyme(Russia) |

Catalytic gas emissions abatement system UTK — 500 (standard configuration) and pre-commissioning activities |

Abatement of ammonia emissions from ammonia compressor |

Ammonia NH3 | 98,1 |

VKG Oil AS VKG Oil AS(Estonia) |

Catalytic gas emissions abatement system UTK — 2000 in explosion-proof housing with chemisorption module. Supervising installation and pre-commissioning activities |

Abatement of aliphatic hydrocarbons, toluene, phenol vapors and others |

Hydrogen sulphide H2S Aliphatic hydrocarbon Benzene C6H6 Ethyl benzene C8H10 Toluene C7H8 |

96,9 |

CRIMSODA CRIMSODA(Russia) |

Catalytic gas emissions abatement system UTK — 6000 with heat recuperation system. Supervising installation and pre-commissioning activities |

Abatement of carbonic oxide emissions in the manufacture of baking powder |

Carbonic oxide СО NOx Hydrogen sulphide H2S |

98,3 |

Iskra Iskra(Russia) |

Catalytic gas emissions abatement system UTK — 100 with heat recuperation system. |

Abatement of phenol, fermentation alcohol and formaldehyde vapors |

Phenol C6H6O Formaldehyde CH2O Fermentation alcohol C2H6O |

98 |

Energomashspetsstal Energomashspetsstal(Ukraine) |

Catalytic gas emissions abatement system UTK – 1000 (standard configuration) | Neutralization of CO emissions from tap-degassing plant to the level of environmental standards | Carbonic oxide СО | 97,5 |

Altai-koks Altai-koks(Russia) |

3 catalytic gas emissions abatement units UTK-5000 | Abatement of ammonia and benzapyrene emissions from pitch granulation equipment | C20H12 Ammonia NH3 |

95 |

Elekond Elekond(Russia) |

NOx selective catalytic reduction unit and acetophenone and acetic acid vapours incenerator | Ventilation emissions abatement from NOx, acetophenone and acetic acid vapours in manganous nitrate production area | Nitrogen oxides NOx | 87,8 |

| NIOST | Catalytic gas emissions abatement system UTK — (explosion proof) | Abatement of ethylene emissions utilizing a technology with the best capital costs to efficiency ratio |

Etherin С2H4 Hexane С6H14 Hexalnethylene С6H12 Ethyl benzene С6H5С2H5 С6H12 Hydrocarbon С4 Hydrogen H2 |

99,9 |

(Russia) |

Chemisorption module and hydrofilter with capacity of 5 000 m3/h | Olkhovatsky sugar factory is a city-forming enterprise, located in a congested residential area. This was the reason why our client’s priority was quick and efficient emissions minimization. |

Ammonia NH3 C2H7N CH3SCH3 C2H6S |

99,5 |

Goal:

Abatement of ammonia emissions from ammonia compressor

Solution:

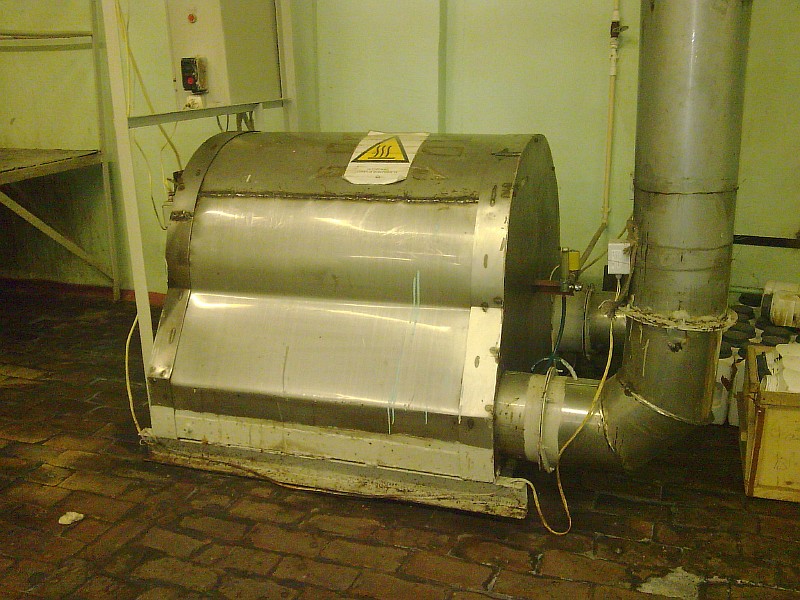

Catalytic gas emissions abatement system UTK – 500 (standard configuration) and pre-commissioning activities

Result:

ЭAbatement efficiency: 98,1%

VKG Oil AS (Estonia)

Goal:

Abatement of aliphatic hydrocarbons, toluene, phenol vapors and others

Solution:

Catalytic gas emissions abatement system UTK – 2000 in explosion-proof housing with chemisorption module. Supervising installation and pre-commissioning activities

Result:

Abatement efficiency: 96,9%

CRIMSODA (Russia)

Goal:

Abatement of carbonic oxide emissions in the manufacture of baking powder

Solution:

Catalytic gas emissions abatement system UTK – 6000 with heat recuperation system. Supervising installation and pre-commissioning activities

Result:

Abatement efficiency: 98,3%

Iskra (Russia)

Goal:

Abatement of phenol, fermentation alcohol and formaldehyde vapors

Solution:

Catalytic gas emissions abatement system UTK – 100 with heat recuperation system

Result:

Abatement efficiency: 98%

Energomashspetsstal (Ukraine)

Goal:

Neutralization of CO emissions from tap-degassing plant to the environmental standard level (≤ 250 mg/m3). Mandatory requirement: catalytic gas abatement system should not create any resistance of outgoing stream from suction pumps exhaust.

Solution:

Catalytic gas emissions abatement system (standard configuration)

Result:

Altai-koks (Russia)

Goal:

Solution:

Abatement of emissions (ammonia, benzapyrene) from pitch granulation equipment

Result:

3 catalytic gas emissions abatement units

Elekond (Russia)

Goal:

Ventilation emissions abatement from NOx, acetophenone and acetic acid vapours in manganous nitrate production area

Solution:

NOx selective catalytic reduction unit and acetophenone and acetic acid vapours incenerator

Result:

Operation of our abatement equipment allowed OAO Elekond to certify company’s environmental management system in compliance with ISO 140001-98. Yearly prevented environmental damage amounts to over 1,5 million roubles.

NIOST

Goal:

Abatement of ethylene emissions utilizing a technology with the best capital costs to efficiency ratio.

Solution:

Catalytic gas emissions abatement system (exp. prf)

Result:

Ethylene abatement efficiency: 99.9% (verified test protocol available)

Olkhovatsky sugar factory (Russia)

Goal:

Abatement of ammonia, dimethylamine and ethyl mercaptan emissions and other hazardous substances in molasses processing department

Solution:

Chemisorption module and hydrofilter with capacity of 5 000 m3/h

Result:

All client’s emissions abatement efficiency requirements were satisfied.

Call us if you have any questions +7 (342) 255-44-39

or we can call you back: Yuliya Shcherbakova

Yuliya ShcherbakovaHead of Sales Department

Sergey Tchistokhin

Sergey TchistokhinSenior sales manager

Valeriya Gushchina

Valeriya GushchinaSales manager