Air Cleaning Systems with Heat Recovery System

ECAT company develops and produces wide range of systems for air purification based on modern catalytic and plasma technologies.

In December 2012 ECAT company participated in “The Union of Architectural and Design Organizations of Perm Region”. Due to it the company starts to develop new areas and to offer the comprehensive solution for air cleaning, which includes not just systems selling, but also the creation of a full-fledged project («turnkey»). The company constantly improves its products and technologies, so constantly conducting R&D to refine and improve the product.

One of the new developments is Heat Recovery System as an additional part of catalytic air cleaning system. Because of it the system solves 2 problems in one time – air purification and increasing of power efficient of entertainment (decreasing of costs for electric and heat power).

All around the world the energy efficiency is the strategic objective of national importance. Meanwhile many companies lose a lot of energy due to insufficient usage of heat produced in technology processes.

Gas heated in the production process uses inefficiency or does not use at all (in this case the gas is wasted to the atmosphere). It leads to huge energy loses in the company, the country and the whole world.

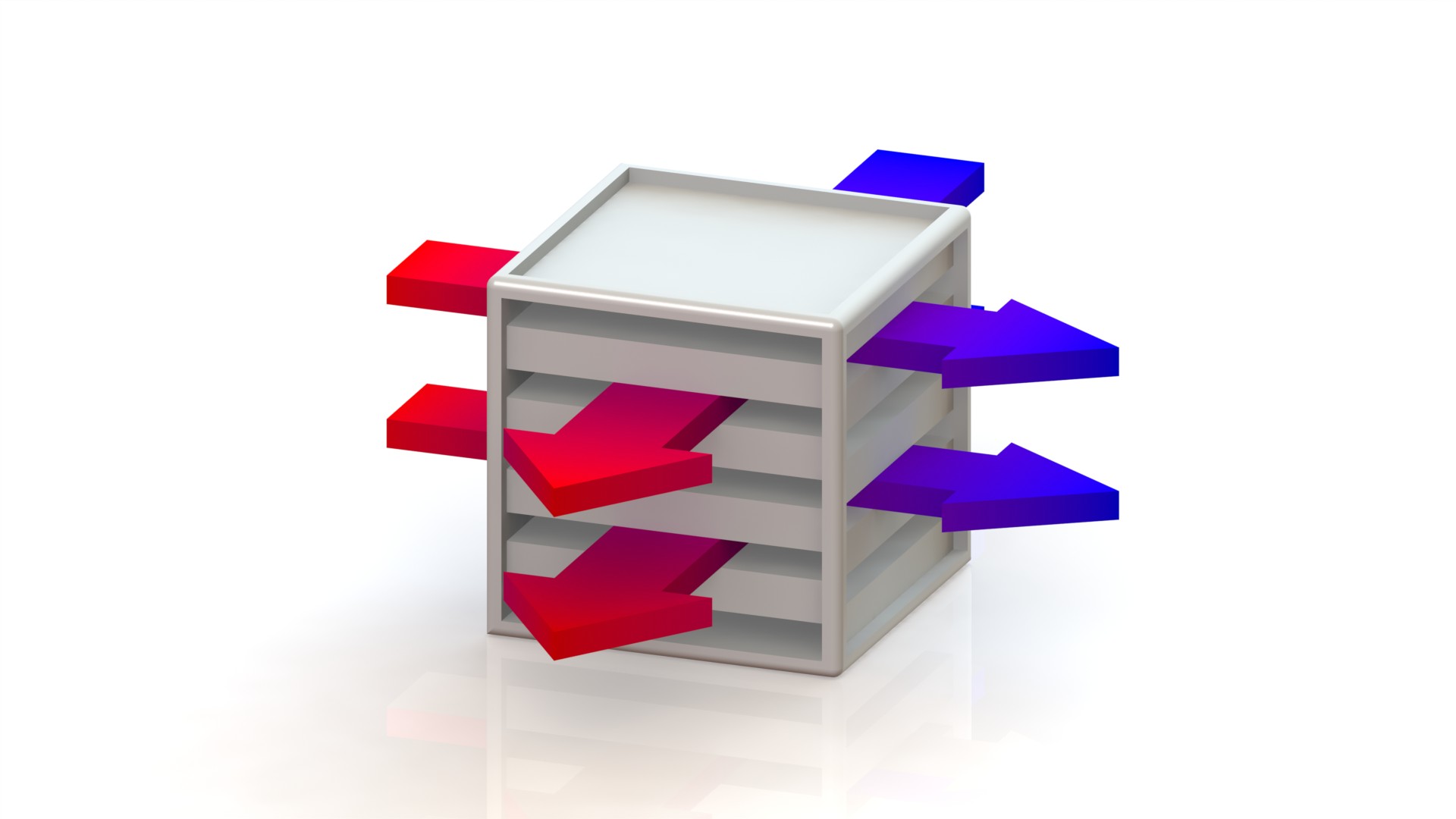

Heat recovery is the heat-exchange process in which the heat is taken from exhaust air and passed to the incoming air. The process takes place in the heat recovery system in the way when these flows do not mix, so the warmed flow can be used in the process and cooled flow can be ejected.

The advantage of recuperation is energy efficiency and cost reduction of exploitation ventilation. In case when there is a limit of possible energy volume and there is no opportunity to place the high-capacity heating system the usage of Heat Recovery System is the best way.

Heat recovery system is a plate heat exchanger through which the heated gas is then purified catalytic cleaning system and clean cool air from the air inlet. The heat of the exhaust gases treated continuously transmitted to the heated incoming fresh air through the wall that separates the environment by enabling the recovery of up to 60% (requires individual calculations for each project). In the case of parallel heat exchangers, the overall efficiency of the system can be up to 85%.

In the process of recovery of net flows and clean air do not mix, so clean heated air can be directed to heating of shops in the autumn-winter period, for pre-drying of parts in the drying chambers, to supply it on the gas burner stoves, etc. So the usage of Heat Recovery Systems will significantly reduce electricity costs, and Catalytic Air Cleaning System with this system is fully repaid in life and even brings additional benefits.

Note that the Heat Recovery System by ECAT company is available with the air cleaning system or separately (it depends on the specific goals of the company). In the case of self-usage in cooled areas recuperative heat exchangers can be used as the reverse way, that is, for the recovery of the cold. In this case, the cold incoming air is transferred from the exhaust air.

ECAT Company renders services on heat calculation, economic calculation, and integration of heat-exchanger modules in the ventilation (with Thermal Catalyst System or separately). The method of calculation of heat recovery, resistance to the gas flow allow to design and deliver high-performance customer installation in accordance with technical requirements for air cleaning industrial and residential use.

Call us if you have any questions +7 (342) 255-44-39

or we can call you back: Yuliya Shcherbakova

Yuliya ShcherbakovaHead of Sales Department

Sergey Tchistokhin

Sergey TchistokhinSenior sales manager

Valeriya Gushchina

Valeriya GushchinaSales manager