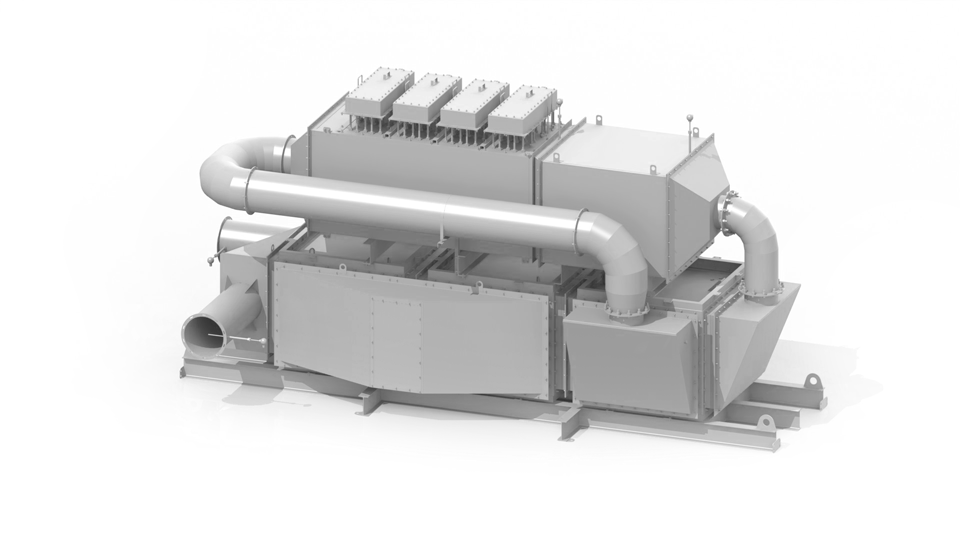

Catalytic gas emissions abatement systems

ECAT Company designs and manufactures catalytic gas emissions abatement systems. Each system is custom designed in full compliance with client’s technical design specification. ECAT Company designs and manufactures catalytic gas emissions abatement systems. Each system is custom designed in full compliance with client’s technical design specification.

Mouse over module name:

Duct

Recuperative module

Heating module

Catalytic reactor

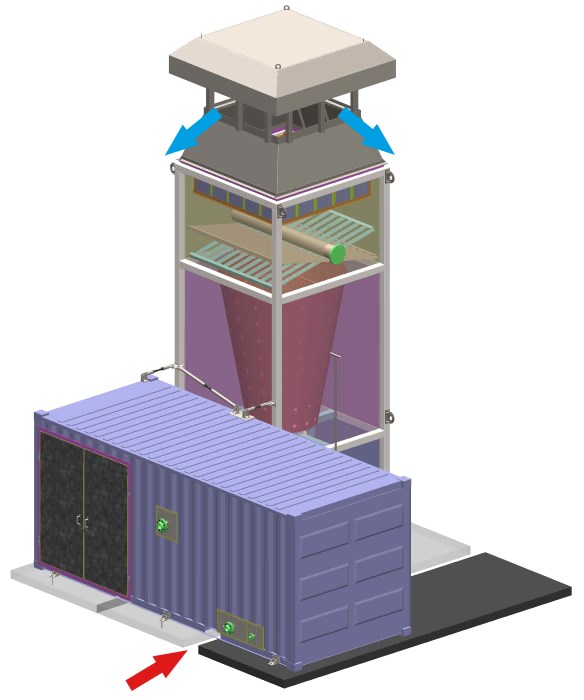

Catalytic gas emissions abatement systems are modular.

Basic configuration consists of the following modules:

Catalytic gas emissions abatement systems are equipped with optional modules when necessary:

Как происходит очистка газовых выбросов?

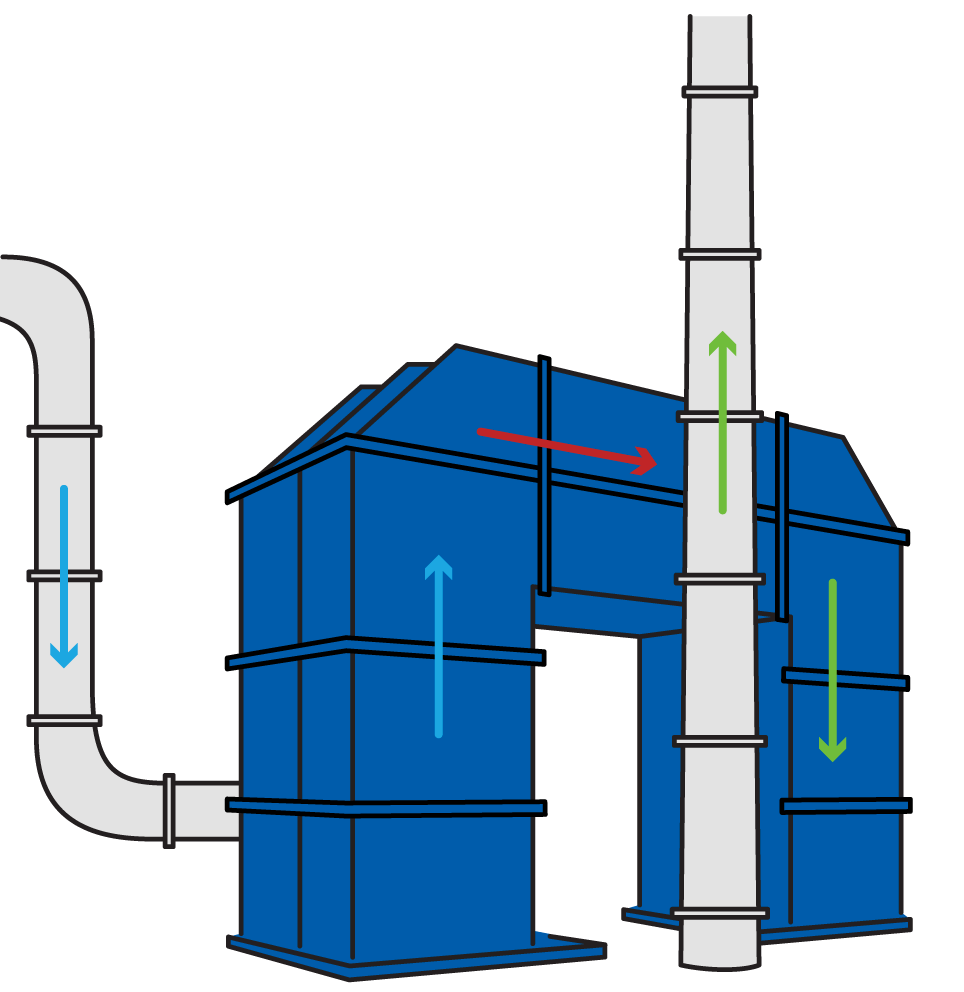

Очищаемая газовоздушная смесь (ГВС), поступающая от источника выбросов, последовательно проходит через модули теплообмена и нагрева. Прогретая до температуры 400-450°С, необходимой для начала протекания каталитического процесса, ГВС направляется в модуль катализа, в котором происходит реакция разложения загрязняющих веществ.

Далее нагретая и очищенная ГВС охлаждается в теплообменном модуле, отдавая свое тепло поступающему в установку выбросу от источника. Работа установки происходит в условиях разрежения, создаваемого вытяжным радиальным вентилятором.

Система автоматического управления контролирует процесс работы УТК, получая данные с термопар и передавая сигналы в модуль нагрева и на вытяжной вентилятор. При необходимости система автоматического управления УТК может передавать параметры работы УТК в систему верхнего уровня посредством универсального протокола связи Modbus.

Regenerative thermal oxidation system

Today regenerative thermal oxidation system is the most efficient abatement solution for VOC process and ventilation in chemical and pharmaceutical industries. Industrial air cleaning by means of RTO system is an economically feasible option for printing plants and paint manufacturers.

High energy efficiency is one of the main advantages of RTO systems. Exhaust gas temperature can be used for air heating in production premises or water or oil heating.

Regenerative thermal oxidation system advantages:

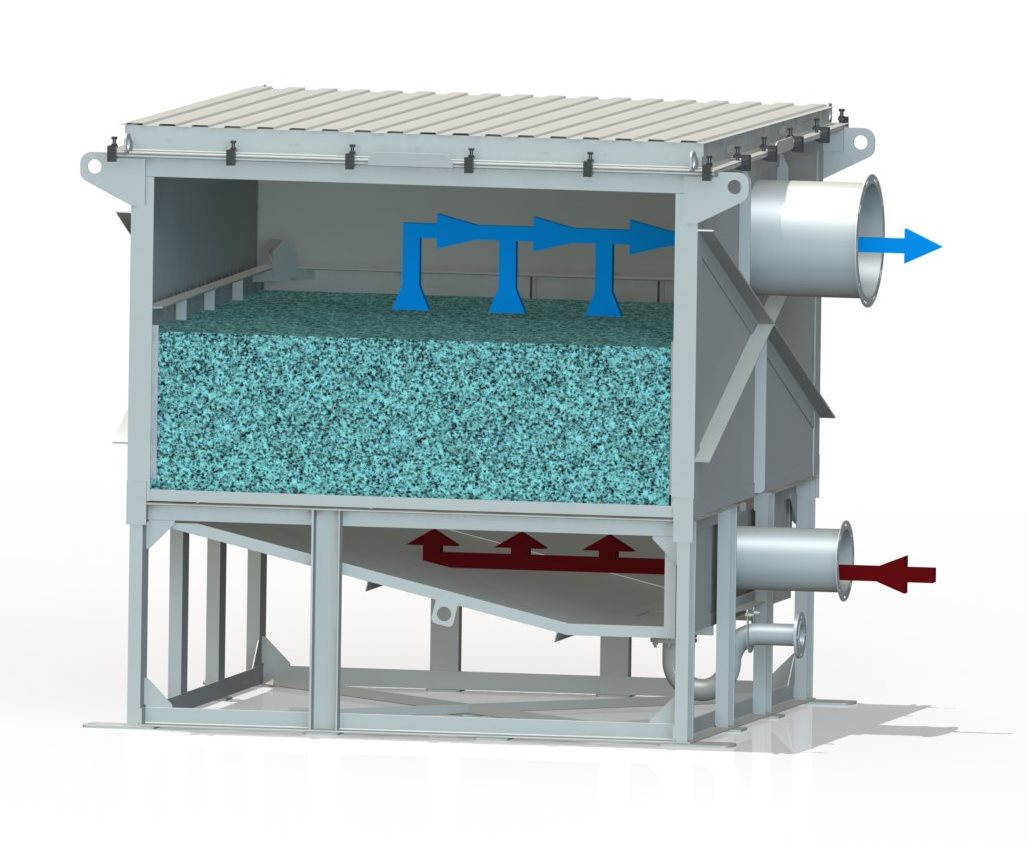

Chemisorption module

Сhemisorption module is specifically developed for sulfur odor, halogen-containing extractives, hydrogen sulphide and ammonia neutralization.

It can be used both as a part of gas emissions abatement system or as an individual unit of equipment in air ventilation system.

Chemisorption module advantages:

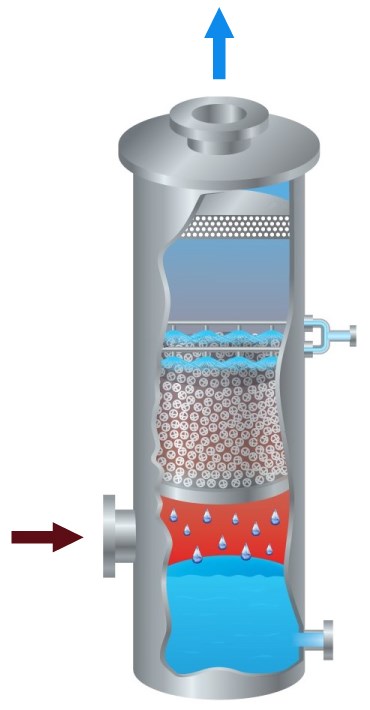

Scrubber

The system is intended for air sterilization and air purification from dust, aerosols and gases in a broad range of volumes and concentrations.

The scrubbers can be installed in the local exhaust ventilation, local exhaust systems, waste gas lines, air purification and recirculation systems.

The principle of the system is based on the neutralization of residual concentrations of pollutants by dint of chemical solution continuously circulating in the scrubber.

The continuity of a cycle with unchanged characteristics is not limited.

Scrubber advantages:

Thermal utilization system

The thermal utilization system is used for cleaning of large volumes of emissions from harmful substances of acid gases.

The system is based on the process of high-temperature oxidation of most volatile organic components (VOCs) and sulfides.

The system allows to achieve abatement efficiency of up to 98% and to obtain safety components — carbon dioxide and water.

The thermal utilization system advantages:

Send

design specification

Our experts will find a solution for you

Download questionnaire

Fill out the questionnaire for your project and e-mail it to info@ecocatalysis.com

Send design specification

Call us if you have any questions +7 (342) 255-44-39

or we can call you back: Yuliya Shcherbakova

Yuliya ShcherbakovaHead of Sales Department

Sergey Tchistokhin

Sergey TchistokhinSenior sales manager

Valeriya Gushchina

Valeriya GushchinaSales manager