Energy efficiency solutions

Energy efficiency is a strategic objective in the majority of world countries. However, there are still many industrial facilities that operate with substantial energy losses due to underutilization of gas heat generated during production processes. Simply because the heat is either used inefficiently or is not used at all, energy losses occur on a factory – wide level.

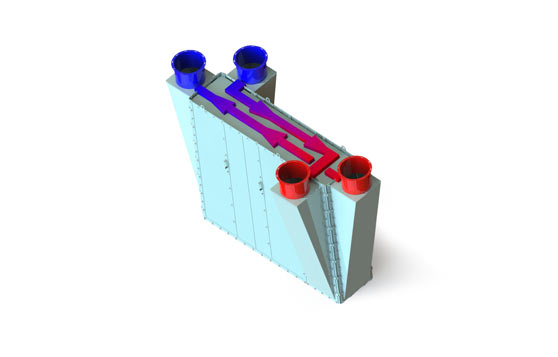

Energy efficiency solution offered by ECAT Company is heat recuperation. It is a heat exchange process that involves heat transfer from exhaust to fresh pressurized air. Heat recuperation system can act as a core module of catalytic gas emissions abatement system or can be operated as. a standalone equipment unit.

Fields of application

Design

Heat recuperation system consists of plate heat exchanger. Heated gas as well as cool air from inlet ventilation go through it. Heat exchange bay consists of profiled plates.

General configuration of recuperator

Main advantages

ECAT Company provides the following services: heat recovery calculation, economic calculation, design of heat exchange modules mounting in ventilation system as part of catalytic gas emissions abatement system or independent from it.

Methods of calculation of heat recovery and resistance to gas flow allow to design, manufacture and commission high-performance custom equipment that fully complies with technical design specification.

Case study

You can find cost effectiveness analysis of thermal oil boiler heat recuperation system

in the table below.

Heat recovery in this project comes to 65%. Provided that production process is continuous, air heating savings would amount to $650 000. This way, recuperation system capital cost repayment period will be around 2,5 months.

| Air volume, м3/hour | 50 000 |

| Exhaust air temperature,°C | 15 |

| Design ambient air temperature ,°C | 13,3 |

| Working day duration, hours | 24 |

| Number of working days per month | 30 |

| Ambient temperature after recuperator, °C | 139,4 |

| Recuperation, % | 65 |

| Average recuperative capacity, kW | 1538 |

| Kilowatt-hour rate (estimated), dollars | 0.05 |

| Air heating savings, dollars | 650 000 |

SEND

DESIGN SPECIFICATION

Our experts will find a solution for you

DOWNLOAD QUESTIONNAIRE

Fill out the questionnaire for your project and e-mail it to info@ecocatalysis.com

SEND DESIGN SPECIFICATION

Call us if you have any questions +7 (342) 255-44-39

or we can call you back: Yuliya Shcherbakova

Yuliya ShcherbakovaHead of Sales Department

Sergey Tchistokhin

Sergey TchistokhinSenior sales manager

Valeriya Gushchina

Valeriya GushchinaSales manager